NOTE: For leaning instructions always consult the

Aircraft’s Operations Hand Book.

Read what Teledyne Continental

Motors Inc.

says about Leaning - Page 26 - 32

![]() Click

Here

Click

Here

Read what Textron Lycoming says about Leaning - ![]() Click

Here &

Click

Here &

![]() More on Leaning Procedures

More on Leaning Procedures

Insight Leaning:

G Series is best technology available, there’s nothing else like it, nothing even comes close.

Operation lean of peak requires special information that only the G3 or G4 Graphic Engine Monitor can provide.

The G Series instruments are extraordinarily capable yet easy to use.

G Series specialized innovative leaning process is the first and only one to ever earn a patent. READ PATENT

Unprecedented in its sophistication, most importantly it makes a complex process easy to accomplish.

Leaning with reference to temperature only is just too confusing for LOP.

Our specialized process reports each individual cylinders status in unambiguous form.

You needn’t ponder if a cylinder is rich or lean we display that too.

Injector Analysis:

Nozzle flow uniformity is paramount to operation lean of peak but only Insight delivers a nozzle analysis every time you lean.

G Series can forewarn of problems and assure uniformity of results. Of course other systems just leave you in the dark.

G Series Data:

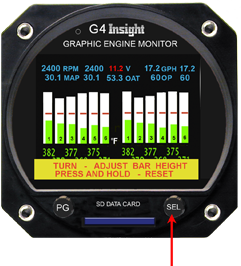

G Series instruments are not just temperature indicators, they compute real-time results using manifold pressure, RPM, fuel flow and temperatures.

G Series handles the raw data to eliminate confusion and provide answers. It couldn’t be easier.

While constantly displaying critical information during flight the G Series always work diligently behind the scenes too, logging data to a handy SD card for study later so nothing is missed.

It’s easy to go back in time, study trends and trace problems to root cause.

Innovation:

Decades ago Insight introduced the first instrument to display cylinder and exhaust gas temperature of all cylinders simultaneously.

This innovation eventually became the industry standard as all other manufacturers followed suit.

Engine monitors depend on numerous temperature probes that have equal potential to inform or confuse when any of them fail.

In fact probe failures can easily be confused with engine failures.

Only the G series has a probe diagnostic system built in.

If

injected you should take your plane up and try a 50

degree lean of peak to see how your injectors are

and here is how to do it with a G2, G3 or G4.

If

injected you should take your plane up and try a 50

degree lean of peak to see how your injectors are

and here is how to do it with a G2, G3 or G4.

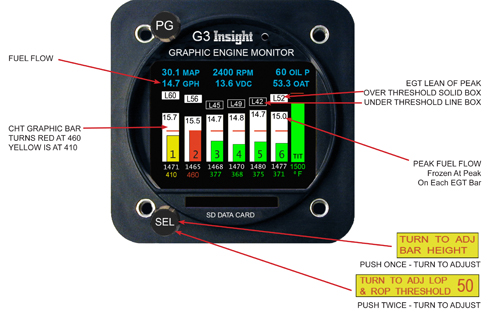

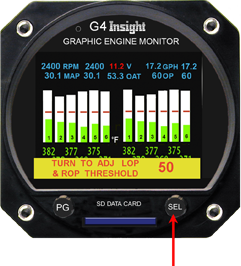

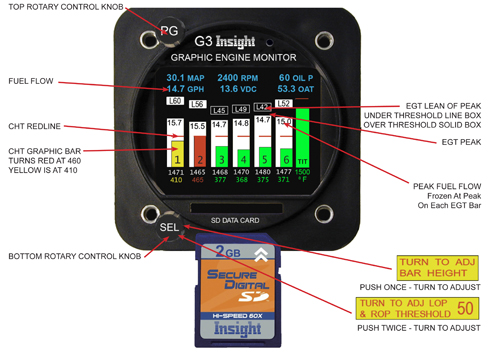

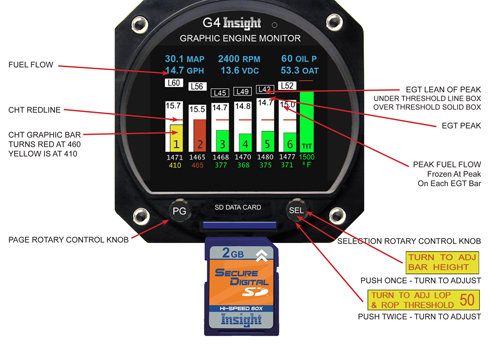

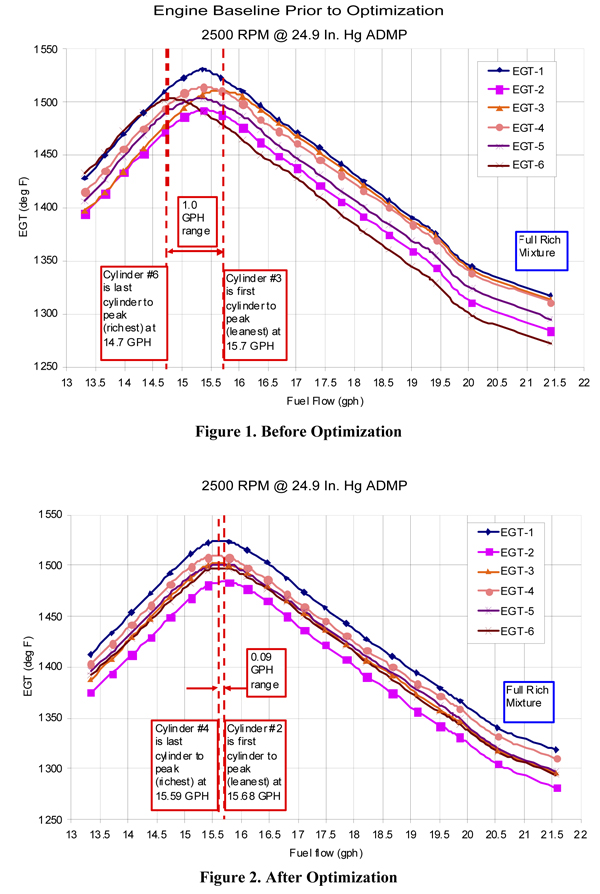

You will know the order of the lean, temperature spread and fuel spread.

You should be under .5 gallons from first to last to lean.

All of this will be on your G Series screen when leaning.

Order of lean is boxes appearing as they hit peak EGT

Temperature distance from peak is the number in the lean box

Fuel Spread is on the EGT columns after EGT peaking

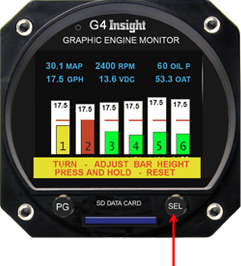

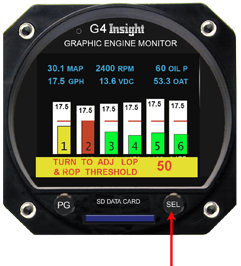

Set Bar Height and Lean Threshold

First push of SEL knob you can adjust EGT bar height on G2-G3-G4 Single and G4 Twin.

Turn SEL knob to adjust height (This should be preset at Insight)

If you have to adjust the bar height every time you have a bad probe (Check probe page)

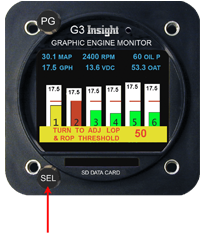

IMPORTANT - Second push of SEL knob you can adjust the lean threshold (rich or lean) on G2-G3-G4 Single and G4 Twin.

Turn SEL knob to adjust threshold (Set to 50) Then push knob

If one injector's fuel flow is higher and still won't freeze on EGT bar after all the other have this could mean a dirty injector.

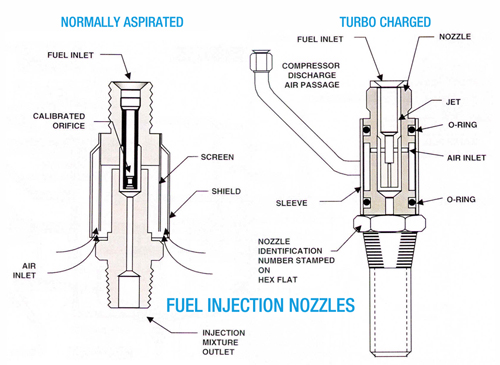

The spray pattern at the nozzle is determined by

the hole shape, size, fuel pressure, and the

amount of ambient or deck pressure air mixed at

the nozzle.

A good spray

pattern will provide maximum atomization and

smooth, consistent engine operation.

Conversely,

a nozzle with a dirty shroud or deteriorated

upper deck shroud seals will not provide the

same spray pattern as a clean unit.

Likewise, if

the calibrated orifice has become damaged due to

rough handling or if the inside diameter of the

orifice has been scratched or chipped by

insertion of safety wire or some other equally

offensive material, the spray pattern will never

be right — despite the cleanliness of the screen

or the condition of the shroud seals.

Here are some Continental charts showing injector fuel spread

A very crucial function is needed for "Running Lean Of Peak" is Insight's exhaust valve analysis in-flight.

"Not on the ground after the damage is done"

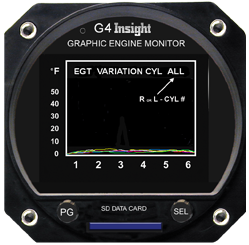

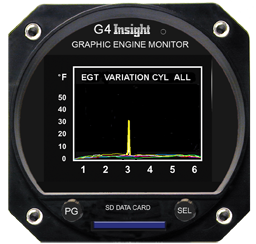

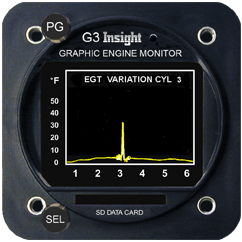

EGT Variation Function is a standard patented feature on all G3, G4 and G9 engine monitors.

This is a new form of engine analysis.

Some valve related engine faults produce a slow periodic variation in EGT.

The oscillation rate is on the order of one cycle every minute or two. This is just too slow to be identified by occasional observation of the temperatures alone. Yet it is very important to discover this phenomenon because it may lead to a catastrophic engine failure. It readily appears in a slow sampled spectrum analysis.

Temperature samples are collected once per second for each cylinder and analyzed each second. The entire sample interval is about 8 minutes. A normal indication will be a flat line with a little noise, while a trouble indication will show as an obvious spectral peak.

Use this page after you lean the aircraft - IMPORTANT - If you see a recurring spike on one of the cylinders you can turn the SEL knob to see which cylinder it is.

You might want to pull that and a good cylinder plug compare and bore scope effected cylinder to see how the exhaust valve looks and compare to good cylinder's valve.

Here is a animated short to see the LOP process of 50 LOP

As each cylinder hits peak the fuel flow freezes on the EGT column.

On the animated image above cylinder 4 is first to hit peak with a fuel flow of 15.5 gallons

On the animated image above cylinder 3 and 5 peaked with a fuel flow of 15.2 gallons

So 15.5 gallons minus 15.2 means the Gami spread here is .3 gallons