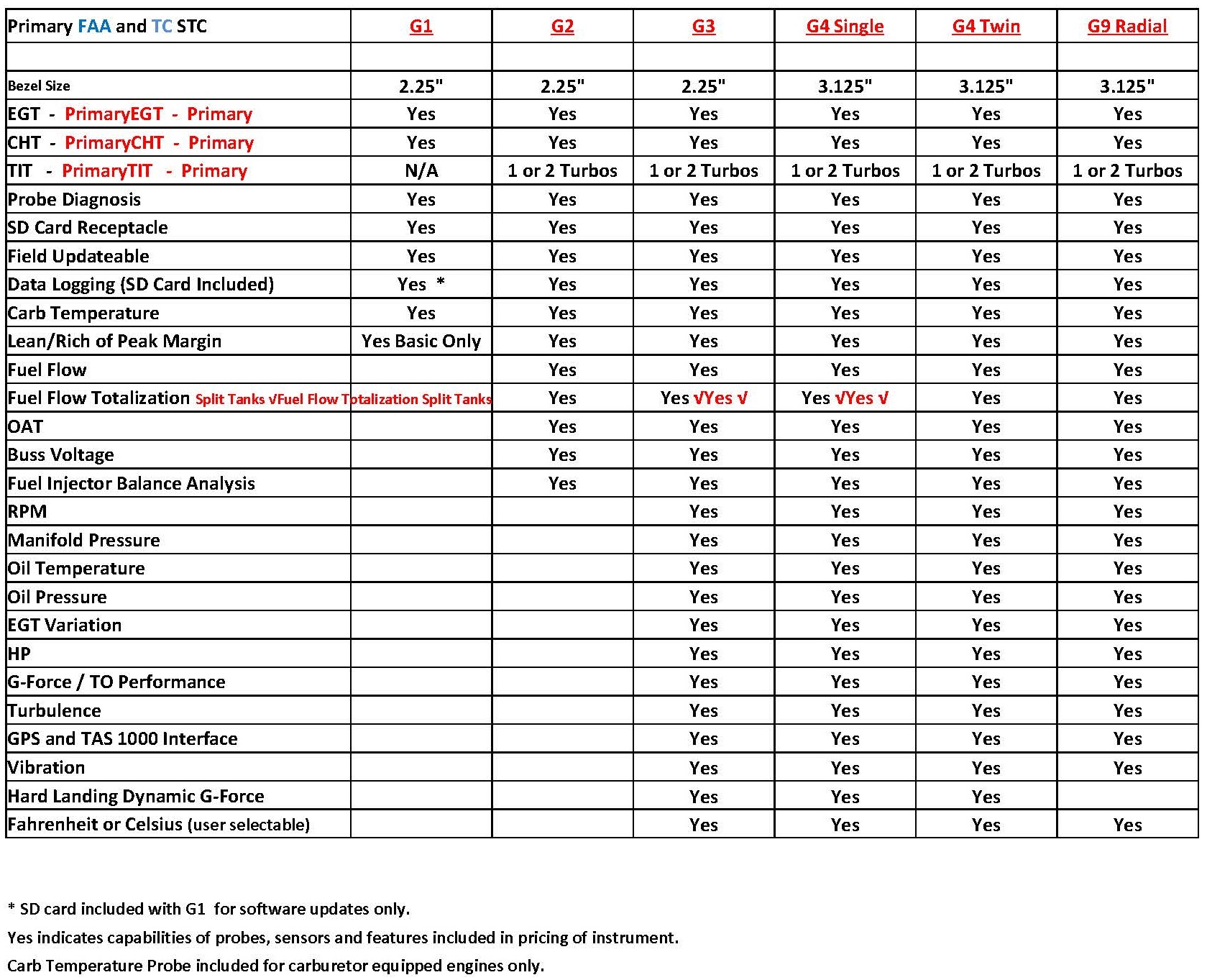

Trust your engine to the best technology available today -- G3-G4

Here's why you should install G3 or G4:

Leaning:

G Series is

the

best technology available, there’s nothing else like

it, nothing even comes close to the advantages

provided by the G Series. Operation lean of peak requires special information

that only the G3 or G4 Graphic Engine Monitor can

provide. The G Series instruments are extraordinarily capable

yet easy to use. G Series specialized

innovative leaning process is the first and only one to ever

earn a patent,

which may be read here.

The G series is unprecedented in its sophistication, and it makes a complex process easy to

accomplish. Leaning with reference to temperature only is just

too confusing for LOP. Our specialized process reports each individual

cylinders status in unambiguous form. You needn’t ponder if a cylinder is rich or lean,

the G Series

will display that too.

Injector Analysis:

Nozzle flow uniformity is paramount to operation lean of peak but only Insight delivers a nozzle analysis every time you lean. G Series can forewarn of problems and assure uniformity of results. Of course other systems just leave you in the dark.

G Series Data:

G Series instruments are not just temperature indicators, they compute real-time results using manifold pressure, RPM, fuel flow and temperatures. G Series handles the raw data to eliminate confusion and provide answers. It couldn’t be easier. While constantly displaying critical information during flight the G Series always work diligently behind the scenes too, logging data to a handy SD card for study later so nothing is missed. It’s easy to go back in time, study trends and trace problems to root cause.

Innovation:

Decades ago Insight introduced the first instrument to display cylinder and exhaust gas temperature of all cylinders simultaneously. This innovation eventually became the industry standard as all other manufacturers followed suit.Engine monitors depend on numerous temperature probes that have equal potential to inform or confuse when any of them fail. In fact probe failures can easily be confused with engine failures. Only the G Series has a probe diagnostic system built in.

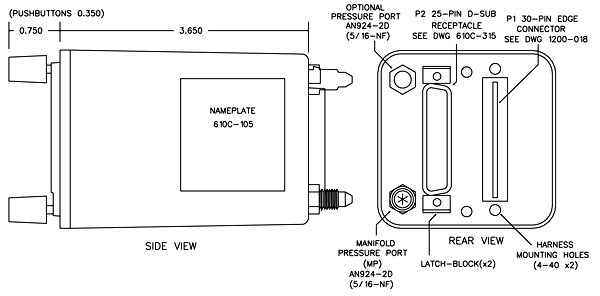

Manufacturing G Series at Insight

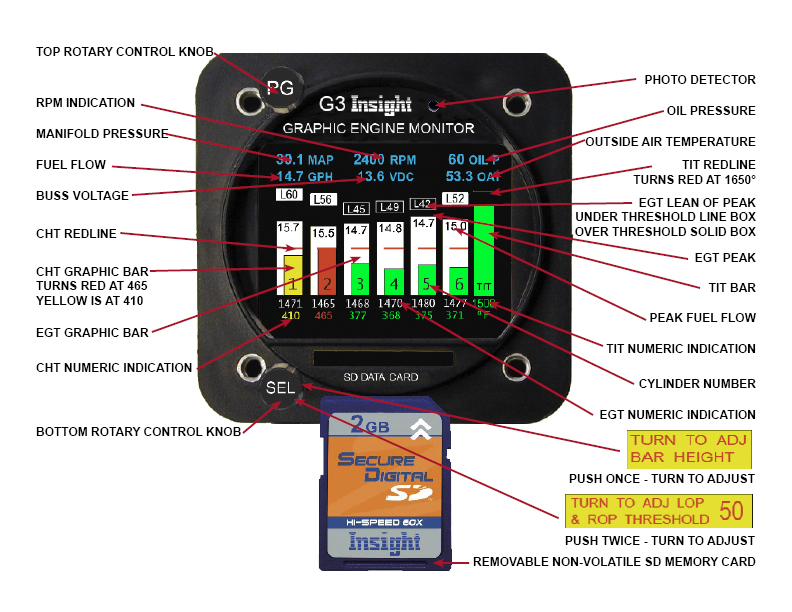

Insight's 610C Graphic Engine Monitor (G3) color-coded bargraph

and digital values may be Primary for CHT, EGT and TIT. All

other data shown in cyan at the top of display are to be

supplementary.

Traditional multi-cylinder exhaust gas and cylinder head

temperature systems that force the pilot to switch or scan

an indicator from cylinder to cylinder in search of critical

engine data, are long obsolete. Using the latest computer

technology, the G3 presents a clear, concise, graphic

picture of all engine temperatures simultaneously for

interpretation at a glance.

Never before has so much engine diagnostic information been

available to the pilot and never before, has the pilot been

able to control mixture with such ease and precision for

peak fuel efficiency.

Insight's latest G3 automatically records flight temperature

and will also interface with other data sources and report

information to other instruments like MFD’s. The data-log

files stored on the SD card can be easily retrieved by the

pilot, in-flight or post-flight, for instant viewing or

permanent record-keeping.

The G3 is a sophisticated tool for engine management. Its

microprocessor performs many tasks that used to be handled

by the pilot. One of the basic functions performed by the G3

is monitoring exhaust gas temperatures for all cylinders

with one degree resolution. What is important is the exhaust

gas temperature of a particular cylinder in relation to its

peak. But peak EGT is not a constant; it changes with

atmospheric conditions, altitude, power setting and engine

condition and for this reason absolute exhaust gas

temperatures in degrees Fahrenheit are quite meaningless.

The real objective of mixture management is finding a

mixture setting which represents the correct position on the

EGT/Fuel Flow Curve. As we will see later, this abstract

task is easily accomplished by the G3's microprocessor which

samples EGT's for all cylinders many times a second and

subjects this data to a complex mathematical analysis can

identify peak. This capability allows the pilot to operate

his or her aircraft engine at the most economical mixture

settings.

It is generally known that EGT can be a valuable source of

information for engine diagnosis and troubleshooting, but

there is a great deal of confusion when it comes to

interpreting this data. One of the basic principles of EGT

engine analysis is that engine temperatures (EGT and CHT)

achieve equilibrium in an engine operating at a constant

power and mixture setting. What is often overlooked is that

this equilibrium cannot be defined as a single point but

rather a range of temperatures.

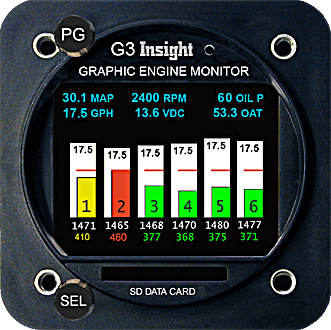

The Graphic Engine Monitor (G3) is ready to operate the

moment electrical power is applied. Within seconds after

starting the engine, the white EGT bar graph columns will

begin to appear on the G3 display. Each column corresponds

to the Exhaust Gas Temperature (EGT) of a cylinder. The

lowest exhaust gas temperature that can be displayed by the

G3 is 800° F. In some engines, the throttle will have to be

opened to the fast idle range to get an EGT indication for

all cylinders. As the cylinder heads begin to warm up, the

display will indicate Cylinder Head Temperature (CHT) for

all cylinders as a smaller green bar in each EGT column. A

horizontal red line across each column represents the

maximum allowable CHT. Digital numbers below each bar graph

column indicates the exact EGT and CHT for each cylinder.

G4 Twin Buss Voltage

The G4 Buss Voltage attempts to display the buss voltage in green when it’s normal and red when it’s outside of normal. In an aircraft with a 12V electrical system the Buss Voltage will be annunciated in green so long as the voltage is 12.0V to 14.9V (inclusive).In an aircraft with a 24V electrical system the Buss Voltage will be annunciated in green so long as the voltage is 24.2V to 28.7V (inclusive). Below this range the alternator isn’t charging the battery and above that it’s overcharging, and the Buss Voltage will be annunciated in red. The instrument must be connected to the main voltage buss (not in series with something else, on a lighting buss, etc.) and must have a good low-resistance ground connection, otherwise the voltage measurement itself will be in error causing the Buss Voltage to indicate in red erroneously.

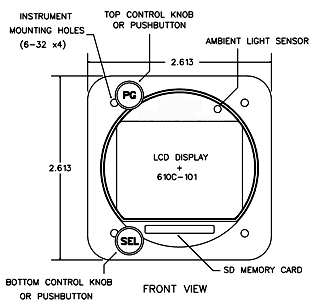

Controlling the G3 instrument

The instrument has two control knobs that operate combination rotary and push button switches. The top knob in general controls screen selection while the bottom knob controls items within the given screen. Each screen assigns its own functional needs to the controls that may change depending on context. A screen may also label the controls with guidance information like “Push to exit”.

The Bar-Graph Display Screen

The Exhaust Gas Temperature is displayed in white bar graph form and is

interpreted much like a conventional mercury thermometer.

The higher the bar, the higher the temperature.

The cylinder head temperature is displayed in green single-bar format. During normal operation it shows as a green

illuminated bar in the lower half of the bar column. Since

EGT is normally higher than CHT, the green bar which

represents CHT is on top of the white illuminated EGT bar

and stands out clearly. However, when the engine is

shutdown, the EGT quickly drops to zero and the cylinders

remain warm for sometime.

The G3 provides a reliable indication of cylinder head

temperature even with the engine shut down. Should an EGT

probe fail, the entire EGT column for that cylinder will go

blank, and the numeric indication will show --- that is

dashes, but the CHT bar will still remain green. The failure

of one probe will not affect the display of any other probe.

An Easy Upgrade

A key requirement of the G3 design was compatibility with previous GEM’s. We strive to never leave our loyal customers behind. Packing all the functionality of the G3 in package half the size of the original GEM took us to the limit of our patience many times but it was worth it. Fortunately its amazingly compact circuits will be built by robotic machines because most of the parts are too small to handle and too difficult to be seen by eye. Products like the modern cell phone have driven the electronic assembly technology we use a long way.

AVWeb Insider - New Insight Engine Monitor and So Much More

By Rick Lindstrom

Insight, the originator of the Graphic Engine Monitor, surprised

everyone by unveiling a new third generation GEM called G3 at

Sun n Fun. By no means a luke warm sequel the G3 is

a breakthrough product.Featuring a bright full color display it offers numerous screens

of new functionality previously unavailable anywhere. While the original lean screen is gone a vastly improved screen

replaces it with special functionality for lean of peak

operation. G3 logs data to readily available SD digital camera cards. A low

cost card will store decades of flight data. The new G3 writes

PC compatible files and directories so no special software is

required to process or transfer data. Its extensive data log

files include flight data from Insight’s TAS-1000 air data

system and nav info from your GPS. Despite its enormous capabilities the new is a compact size and plug-compatible replacement for all previous

GEMs. Insight offers a generous GEM trade-in to make upgrades

easy.

Restarting The Leaning Process

Restart the leaning

process and resetting the peak indications on G1 by short push

of bottom button.

Restart the leaning process and resetting

the peak indications on G2/3/4 single by a short push of the SEL

button.

Holding the SEL knob for about 3 seconds on G4 twin

will take you back to twin-engine screen.

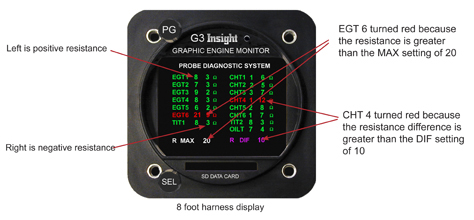

Probe Screen

The

Need for better Diagnostic Tools

The

Need for better Diagnostic Tools

Troubleshooting avionics is an expensive and time-consuming process. Often times the procedure requires access to the instrument connector for continuity measurements. This might take hours of instrument panel disassembly just to touch the connector. We needed something better, easier to use, less time consuming and therefore less expensive.

Why not have the instrument diagnose itself? Then you don’t have to disassemble the airplane or even touch the wiring. This is not as easy as it might seem. Adding resistance measurement hardware for each and every probe wire would more than double the complexity of the measurement system. I considered this carefully during the development of the GEM-610 second generation instrument. It would at least add a second PC board to the instrument and have even greater adverse impact on the GEMINI twin version. Even if we endured these problems to get the information we had no practical way to display it on an orange bar display.

So I abandoned it then, but revisited again this time. The new color display was certainly adept at displaying the information, eliminating that problem, but the resistance data was still hard to get.

So this time I was able to invent a new way of measuring resistance. The simple idea worked beautifully without adverse impact on the design. It was so simple in fact even I was skeptical at first.Without this simple breakthrough we’d still be diagnosing things the hard way.

So what does the diagnostic system do?

The probe diagnosis page indications are in green for normal readings and red for readings that fail the criteria set at the bottom of the screen.

Each temperature probe consists of two wires, a

positive lead and a negative lead. The two

numbers next to each identifier show the

resistance in Ohms of each lead.

For example, the line EGT1 8 3 means the

positive lead of the EGT1 probe has 8 Ohms

resistance, and the negative lead has 3 Ohms

resistance.

When the probe is new, it will have relatively

low resistance.

As the probe ages, it’s resistance will slowly

go up. Eventually, the probe will measure

outside the pas/fail criteria you set at the

bottom of the screen, and change from green to

red, indicating that the probe should be

replaced before it fails and leaves you with no

temperature reading at all.

One other point to consider is that the longer

the wiring to the probes, the higher its

resistance.

Every foot of EGT wire adds 1.7 Ohms/ft for the

+ lead and 0.8 Ohms/ft for the - lead. Every

foot of CHT wire adds 0.8 Ohms/ft for the + lead

and 1.2 Ohms/ft for the - lead.

A 24 ft harness will fail the criteria that an 8

ft harness will pass with. That is why we allow

the user to modify the pass/fail criteria on the

bottom of the screen.

The meaning of the

pass/fail criteria is as follows:

R MAX sets the maximum resistance (in Ohms) that

any single lead may have. If the R MAX is set to

20 Ohms a probe with either the positive or

negative leads measuring greater than 20 Ohms

will be annunciated in RED, otherwise its

displayed in GREEN.

R DIF sets the maximum resistance (in Ohms) that

the positive lead may differ from the negative

lead. If R DIF is set to 10 Ohms, the positive

and negative leads need to measure within 10

Ohms of each other to be annunciated in GREEN,

otherwise it is RED

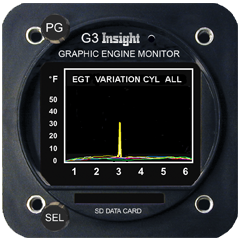

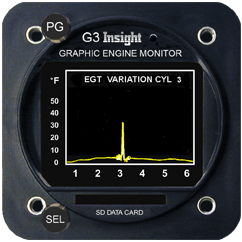

EGT Variation Screen - View Mag Ad.

This

is a new form of engine analysis.

This

is a new form of engine analysis.

Some valve related engine faults produce a slow periodic

variation in EGT. The oscillation rate is on the order of one cycle every minute

or two. This is just too slow to be identified by occasional

observation of the temperatures alone. Yet it is very important

to discover this phenomenon because it may lead to a

catastrophic engine failure. It readily appears in a slow

sampled spectrum analysis.

Temperature samples are collected once per second for each

cylinder and analyzed each second. The entire sample interval is

about 8 minutes. A normal indication will be a flat line with a

little noise, while a trouble indication will show as an obvious

spectral peak.

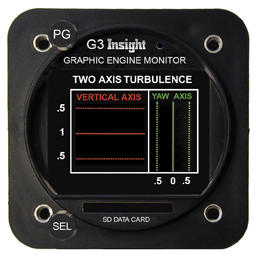

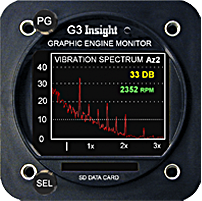

Vibration Screen

New Capabilities for the Next Generation G3 GEM

If you take a step back from the EGT/CHT idea to explore engine monitoring in general, you discover that at least half the engine monitoring solution is missing. EGT analysis reveals combustion phenomenon but simply ignores mechanical problems.

By the time a mechanical problem shows up in EGT, if it ever does, the damage is done and it is far too late to do anything about it.

Vibration analysis is the key to pre-emptive detection of mechanical problems.

Following the update of the G3 Graphic Engine Monitor to V1.78 or higher, the Vibration Analysis screen will now appear among the supplementary screens when the PG knob is turned. In order for the vibration analysis to function your G3 must be equipped with a vibration sensor and a connection to the magneto for RPM measurement. If your instrument was purchased prior to September 2011, Insight will be sending you a vibration sensor shortly. Instruments purchased after this date will ship with the sensor included with the main kit.

After the electrical connections to the sensor are made, then sensor may be tested simply by powering up the G3 and vibration sensor. It is not necessary to start the engine to perform this test. The sensor LED should flash briefly and rapidly when power is first applied until communication is established with the G3, at which time the LED blinks more slowly (approximately once per second). When the LED indicates communications with the G3 has been established select the Vibration Analysis screen by turning the PG knob. While observing the vibration graph disregard the “RPM Required” message and rap lightly on the vibration sensor with the handle of a screw driver. The graph should register the impacts.

The sensor should then be firmly mounted directly to the engine case, preferably oriented in such a manner as to match the small airplane symbol engraved on the sensor body. In some rare cases it may not be possible to mount it in this manner, and the installer will have to fabricate an appropriate bracket or else be prepared to compensate for the change in orientation when viewing the vibration data. A representative installation is shown in the following figure:

Using the Vibration Analysis Screen on the

G3:

The sensor detects vibration in all 3 axis (fore-aft labeled x, up-down labeled z, and left-right labeled y) which are presented on different sub-screens. The vibration analysis only functions when the engine is running and a valid rpm signal is detected.

In regards to the vibration graph, the vertical axis represents the amount of vibration energy and the horizontal axis represents the frequency spectrum expressed as multiples of crankshaft rpm. When the engine is running, the screen will come alive with a waveform that represents the engine motion, presented in a spectral format with the crankshaft energies appearing at the 1x mark on the bottom scale. Propeller vibration will likewise be synchronous with the crankshaft vibration. Other sources of vibration will tend to produce energies at other frequencies.

For example, camshaft vibration tends to accumulate at the .5x mark, since the cam turns at 1/2 the rate of the crankshaft. Magneto vibration will appear at 1.5x mark in a 6-cylinder engine. Alternator vibration may appear somewhere around 3x or 4x, depending on the ratio it is driven at.

A gear-driven alternator may appear in a different axis than the crankshaft does if it is mounted at 90deg to the engine, although ANY source of vibration will show some energy in all three axis. Complex vibration as generated by reciprocating machinery will also produce a great number of harmonic spikes, which at first glance may seem confusing. The user should experiment with running the engine at different power settings under different conditions to get a feel for what is a "normal" spectrum for their particular engine. A simplified case of vibration is shown in the following figure:

In the example shown above the main source of energy is at the 1x mark, and represents the crankshaft rpm. The smaller spikes at the 0.5x mark and the 1.5x point are probably created by the camshaft and the magneto, respectively. The user should be aware that a multi-cylinder reciprocating engine produces energies at a multitude of frequencies and directions, which reinforce and subtract from each other to create a very complex waveform. It is the responsibility of the user to gain familiarity with a waveform that is typical of their particular engine, so that unusual readings can be detected and interpreted.

The user may examine the various sub-screens by pushing the top button (PG). There are presently six screens to examine, each of the primary axis (X,Y and Z) and an averaged version of each (denoted Ax, Ay, and Az). The averaged version will be much "cleaner" and contain less noise than the raw measurement and is the preferred screen to examine for each axis. The bottom knob (SEL) controls a cursor which will "snap" to nearby vibration spikes to make it easy to examine them closer. The bottom knob can also be pushed to enter a zoom mode. When in zoom mode, turning the bottom knob will allow you to scroll through the waveform. Continue to press the bottom knob to set progressively higher zoom modes. A further press when at maximum zoom will return you to the overall view.

Pressing and holding the PG button will trigger the G3 to save the present vibration waveform for future reference. The waveform will be stored as a series of hexadecimal bytes in the current log file. Insight can provide a tool for examining this waveform using Excel or a similar spreadsheet. The tool is presently in the earliest functional stages of development, and will be improved over time.

It is expected that the vibration functions will be used as a "condition-monitoring tool". Since every engine and accessory combination is different, everyone's vibration spectrum will look unique and it would be impossible to generalize the interpretation of the spectrum. The user will come to recognize what a "normal" spectrum looks like for their engine and by periodically scanning the vibration screen can recognize when potential trouble is developing. When a new spike appears or an existing spike begins to show signs of higher than normal amplitude further investigation is warranted. The source of the spike can be interpreted by noting its primary axis and its frequency relative to crankshaft RPM as discussed above. By periodically saving their vibration data as discussed above, the user can create a database of reference waveforms for future comparison.

While in-flight with the vibration screen showing on G3, Pressing and holding the PG button will trigger the G3 to save the present vibration waveform for future reference.

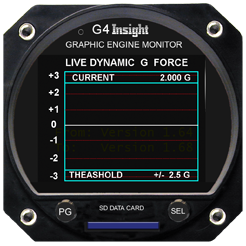

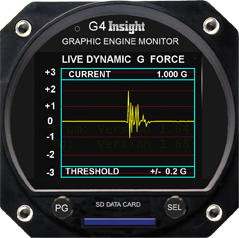

Take Off G Force Screen

Turbulence Display Screen

The G3-4 contains a 3-axis accelerometer sampled at modest rates to measure turbulence and landing shock. Knowledge of G forces will help the pilot to operate the airplane safely by slowing to maneuvering speed. Landing shock is a good training aid for smooth landings and a predictor of structural damage. Data logged G force will report unauthorized aerobatic activity or abuse of rental aircraft. It could also be useful in accident investigation.

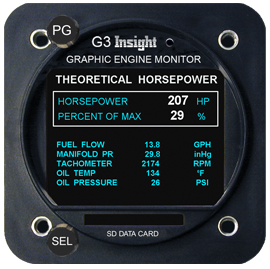

Measuring Horse Power Screen

On

a test stand engine horsepower is derived by measuring the

twisting force (torque) that the engine exerts on a load. In

fact horsepower is defined as simply the product of torque times

RPM. Therefore

if our piston engines were equipped with real torque transducers

we could utilize RPM and compute real horsepower. While such

torque transducers are commonly used to calibrate turbo-prop

engines they actually cost more than a typical piston engine.

Sadly there is no practical way to directly measure horsepower

in a piston aircraft engine. But

this hasn’t stopped at least one engine instrument manufacturer

from making bogus claims to the contrary!

On

a test stand engine horsepower is derived by measuring the

twisting force (torque) that the engine exerts on a load. In

fact horsepower is defined as simply the product of torque times

RPM. Therefore

if our piston engines were equipped with real torque transducers

we could utilize RPM and compute real horsepower. While such

torque transducers are commonly used to calibrate turbo-prop

engines they actually cost more than a typical piston engine.

Sadly there is no practical way to directly measure horsepower

in a piston aircraft engine. But

this hasn’t stopped at least one engine instrument manufacturer

from making bogus claims to the contrary!

REMEMBER: There is no

practical way to truly measure horsepower.

If you planned to use your horsepower display to gauge take off performance or measure engine health you can forget it. In fact, dynamometer tests of so-called horsepower displays revealed NO CHANGE in indicated “horsepower” even when individual cylinders were completely disabled!

The Insight Approach to Power

Despite some limitations we elected to put a power display in the G3 graphic engine monitor. To prevent any misconceptions we called it “Theoretical Horsepower”, and under certain conditions it actually does a pretty good job of reporting horsepower. One dependable metric of power is fuel consumption. At peak EGT and leaner where ample or excess oxygen available to consume the available fuel horsepower is a linear function of fuel flow. At richer mixtures where some fuel remains unconsumed and doesn’t contribute its full power potential the simple linear relationship falls apart. Prior to leaning to peak the display is challenged to deliver an accurate horsepower display but once peak has been reached the rich-of-peak accuracy will improve.

One limitation of the fuel method is that it is not sensitive to

engine faults that can significantly affect the power produced.

For example, a cylinder without ignition won’t combust the fuel

to produce power, but will nevertheless continue to consume it.

So don’t expect to diagnose engine performance issues with the

fuel flow approach to horsepower calculation.

What good is a fuel flow based horsepower calculator? The intended purpose of the theoretical horsepower display is to provide an indication of power for leaning purposes. For example, lean-of-peak operation is not recommended at power settings greater than 65%. It is interesting to see the reduction in horsepower that accompanies lean of peak operation.

The Insight Approach to Performance Measuring

While the G3 does not directly measure true horsepower (remember that no engine monitor does) it does measure the EFFECT of horsepower on takeoff acceleration. This information is displayed on the “Take Off Performance” screen and recorded in the log file too. Acceleration is direct function of engine thrust and other factors like weight, runway conditions, slope and even tire pressure. Of course, ambient conditions like altitude and temperature will affect engine power and therefore take off performance.

Insight announces the next big breakthrough in engine monitoring

In G Series Software Version 208 the G3-4 has a new page that displays data received from the TAS-1000.

The GEM's data-logging capabilities can be extended by receiving air data from a TAS-1000 air data computer. This page shows real-time air data which includes True Airspeed, Pressure Altitude, and Wind Speed and Wind Direction all of which are recorded in the GEM's data log along with engine and fuel data.

Insight’s G3-4 is now capable of receiving RS-232 serial data from our TAS-1000 MFDS that includes Indicated Air Speed, True Air Speed, Pressure Altitude, True Air Temperature, Wind Direction, Wind Speed, and Heading in the data log file on every flight.

While the detail in the G3-4 data log is unprecedented – now it is even better.

The G3 engine log system has been transformed to a complete aircraft performance logging system.

Now you can log aircraft performance data right along with your engine data.

The missing link in data log analysis is finally available.

Now you can really tell what’s happening. Much of the black-box functionality previously available only in Jets is now available to you.

The key to operating your aircraft efficiently is understanding its performance. Now every data log is like a performance chart from the flight manual but it is specific to your aircraft and actual conditions.

Don’t forget about the Insight TAS 1000’s ability to fill in your GPS pages with real-time air data, fuel, wind data page and also with wind arrow and wind speed on your moving map.

With no TAS the G3-4 displays

only OAT (Outside Air Temperature) but with

a TAS-1000 the missing link in data log analysis is finally available.

With the TAS installed in addition to OAT the G3-4 displays also displays

- TAT (Total Air Temperature)

- IAS (Indicated Air Speed)

- TAS (True Air Speed)

- ALT (Pressure Altitude)

- WD (Wind Direction)

- WS (Wind Speed)

- HDG (Heading)

Turbulence and Hard Landings:

Now we go back in time to capture a turbulent transient or a landing event. In the miscellaneous configuration screen the pilot can now set the threshold for the vertical axis G-force. Every time this threshold is exceeded the G3/G4 records a 12 second interval of the turbulence in the log file. These twelve seconds consists of data from the 6 seconds before the event and the 6 seconds after it. There are two new screens between Two Axis Turbulence and Takeoff G-force which display live G-force and a snapshot of the G-Force from last event (threshold exceeded). User can view a graph of the last 12 seconds of live data or view the last captured event.This feature will also capture hard landings.

The graph is automatically scaled for maximum zoom based on threshold. When the threshold is exceeded the 12 second G-force is also recorded in the log file.

The new transient G-force screen shows you the whole event the moment it happens. You won’t miss a thing.

The event is also marked and stored in the log file for easy reference later.

The pilot can set the trigger threshold on the G-force screen for normal operation. Just prior to landing the instrument automatically resets that threshold to always capture the landing event. Just 6 seconds after touch down a high resolution picture of the landing is available.

It is all automatic and couldn’t be easier.

This new feature is available on all new G3 & G4 instruments and is available at no charge to all current customers in the latest update.

Just download and update your instrument from our web site.

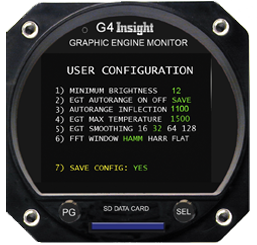

User Configuration

G3-G4 have same screens

Using the knobs to

navigate the G3-4:

The G3-4 has two knobs: PD

select page and SEL work within page. There are two

functions built into each knob; the push button

switch activated by pressing the knob in, and the

selection is activated by turning the knob either

clockwise or counter clockwise.

The PG knob

is used to select the various screens. From the main

temperature bargraph screen turn the PG knob counter

clockwise 2 clicks to get to the User Configuration

screen. Once you are there you do not use the PG

knob any more because turning it takes you away from

the User Configuration screen.

The SEL button

is pressed to select a line for adjustment. When you

first enter a screen by default no line is selected.

Pressing the SEL button once selects line 1. The

selected line is shown in yellow. Pressing it a

second time selects line 2. On any line with

multiple selections the selected item will be shown

in red.

Setting up the G3 Temperature

Bargraph Display:

On the User Configuration

screen there are some options for setting up the

temperature bargraph display. There are three

different ways to accomplish this. One method is to

use the Auto range function to configure the display

for you.

Another method is to adjust the MAX EGT

TEMPERATURE and AUTORANGE INFLECTION parameters

manually, and a third method is to set the bar

heights visually on the main screen.

On line

2 (EGT AUTORANGE) there are 3 possibilities ON OFF

and SAVE. After pushing the SEL button until this

line is highlighted in yellow, the SEL knob may then

be turned to make a selection on this line. When on

line 2 turning the SEL knob fully counter clockwise

selects nothing. From there turning the SEL knob one

click clockwise selects ON. The current selection is

shown in red. Turning the SEL knob another click

clockwise selects OFF. And one more turn clockwise

selects SAVE.

Using the Auto Range function

(Method 1):

To turn OFF the auto range

capability on the User configuration screen:

Press the SEL button twice to select line 2 (EGT

AUTORANGE).

Turn the SEL knob to select OFF on

line 2.

Press the SEL button to select line 7

“SAVE CONFIG”

Turn the SEL knob to select YES on

line 7.

Press the SEL knob to save the choice.

We have now turned off auto ranging.

To turn

ON the auto range capability on the User

configuration screen:

Press the SEL button to

select line 2. (EGT AUTORANGE).

Turn the SEL knob

to select ON on line 2.

Press the SEL button to

select line 7 “SAVE CONFIG”

Turn the SEL knob to

select YES on line 7.

Press the SEL knob to save

the choice.

We have now turned on auto ranging.

In order to use the

auto range function it must be turned on as

described above. Once this function is enabled, the

G3-4 will automatically adjust the EGT MAX

TEMPERATURE and AUTORANGE INFLECTION to be

appropriate for the highest temperature reported by

the probes.

You should now take the airplane and

perform a typical flight.

The G3-4 will analyze

the EGT temperatures and scale the temperature bars

as required so that the entire temperature range

measured by the EGT probes is displayed on the main

bargraph screen.

It is important to realize that

so far this adjustment is temporary. If we want it

to remain permanent we must return to the User

Configuration screen.

To save the results of auto ranging:

- Press the SEL button to select line 2 (EGT AUTORANGE).

- Turn the SEL knob to select SAVE on line 2.

- Press the SEL button to select line 7 “SAVE CONFIG”

- Turn the SEL knob to select YES on line 7.

- Press the SEL knob to save the choice.

- The results are saved, and auto ranging is turned OFF.

The main temperature

bargraphs should now be scaled properly for this

individual airplane on all subsequent flights.

Auto ranging may be turned on and the range

relearned as often as desired.

Setting up the G3 Temperature Bargraph display manually (Method 2):

In some cases it may be desirable to set or

refine the temperature bargraph screen manually.

To do so, return to the User Configuration screen

and make sure EGT AUTORANGE is turned OFF as

described earlier. Adjust EGT MAX TEMPERATURE and

AUTORANGE INFLECTION directly by using the following

procedure:

To set an EGT MAX TEMPERATURE and AUTORANGE

INFLECTION on the User configuration screen:

Press the SEL button to select line 3 (AUTORANGE

INFLECTION) or line 4 (EGT MAX TEMPERATURE).

Turn

the SEL knob to select a value as desired. Notice

that adjusting the AUTORANGE INFLECTION affects the

value of EGT MAX TEMPERATURE and vice versa.

Press the SEL button to select line 7 “Save Config”

Turn the SEL knob to select YES on line 7.

Press

the SEL knob to save the choice.

AUTORANGE INFLECTION and EGT MAX TEMPERATURE explained:

The Autorange Inflection point is the point

along the temperature graph at which the scale of

the bars change.

Below the inflection point (ie,

at low temperatures) readings are displayed with a

coarse resolution (the bars go up/down a small

amount for a relatively large change in

temperature).

Above the Inflection Point (at

higher temperatures than the Inflection Point) the

bars are displayed in a higher resolution (the bars

go up/down more for a small change in temperature).

The net effect is that the dynamic range of the

temperature bargraph is increased. In other words,

we can show temperatures all the way down to room

temperature on the bargraph yet still show small

changes in temperature at the airplane’s operating

temperature range.

As an example if we set our

Autorange Inflection to be 1200 deg then

temperatures below 1200 will be rendered with

relatively few pixels/degree whereas temperatures

above 1200 will be rendered with more pixels/degree

to make temperature changes more obvious.

The EGT Max

Temperature simply defines the temperature that is

represented by a bar that is full screen in height.

For example if EGT Max Temperature is set to 1600

deg than a temperature of 1600 deg will be rendered

as a bar that reaches the top of the screen.

The G3’s Autorange Inflection is always 400 deg

below the EGT Max Temperature. Adjusting one will

therefore always affect the other automatically.

EGT Smoothing

The lower the number the faster

the sampling but less smooth (jumpier)

The factory

preset is 32.

Adjusting the bar heights from the main screen (Method 3):

An alternative way to setup the scale of the

temperature bargraphs can be performed from the main

screen.

Press the SEL button and a message

appears: “TURN-ADJUST BAR HEIGHT”.

By turning

the SEL button the heights of the bars may be moved

up and down.

Pressing the SEL button twice more

returns the G3-4 to its normal mode.

If we

return to the User Configuration screen, we will see

that EGT MAX TEMPERATURE and AUTORANGE

INFLECTION have been adjusted to reflect our changes

to the bar height.

If the adjustment is to

become permanent we must select Save Config and set

it to yes.

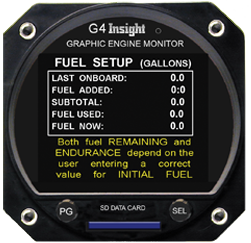

NEW Fuel Screens

Previously, there was no standard color scheme in the configuration screens.

Now, the selected line is yellow and the inactive lines are white.

YES/NO

in red has been removed by displaying only the word YES or

the word NO in green, when saving.

When there is a

choice of several items the selected item is displayed in

green.

Exactly one item is always selected.

The

choices of temperature units are Celsius or Fahrenheit then

either Fahrenheit or Celsius will be selected in green.

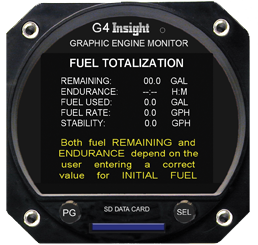

The FUEL TOTALIZATION screen has been improved and is even easier to use.

This change allows the pilot to see this screen before entering fuel on board.

Also setting initial fuel can be checked and corrected in

flight.

Previously the pilot had to enter the amount of

fuel onboard before he could view the Fuel Totalization

page.

Now both the FUEL TOTALIZATION page and the

FUEL

SETUP page are accessible at any time.

On the

FUEL

TOTALIZATION screen simply press the PG (left) button to

enter fuel, press it again when done. As before you can

top up the tank(s) by turning the SEL (right) knob counter

clockwise on the very first click.

Set total fuel onboard before take-off

Your G2-3-4 was preset at factory with your usable total fuel

To reach the FUEL TOTALIZATION screen from the main screen:

- Turn the PG knob counterclockwise one click.

- Push PG knob to go back and forth between the FUEL SETUP and FUEL TOTALIZATION screens

- On FUEL SETUP screen setting fuel gallons the lines FUEL ADDED, SUBTOTAL and FUEL NOW color will be yellow.

- Turn SEL knob to set gallons (Clockwise or Counterclockwise one click for total preset total fuel for your aircraft)

- At any time, you can push PG knob to go back and forth between the FUEL SETUP and FUEL TOTALIZATION screens to add more fuel.

G3-G4 have same screens

FF Stability

Displays, literally, the stability of your fuel flow over the last few seconds. The smaller the number, the less the fuel flow has varied in the past few seconds. A well-regulated fuel system will have a small number, a carbureted system can expect a larger number. The smaller the number the more likely you are to get an accurate fuel flow reading during the lean-find function. An larger number will make things more difficult.

GEM FUEL TOTALIZER CAUTIONARY NOTICE

The Fuel Remaining display on the GEM is very useful but is not without limitations. Understand first that the factory fuel quantity gauges are the only instruments in the panel that physically measure fuel level. They are still the primary indication of fuel level in the airplane.

The GEM doesn’t measure level, but instead measures only fuel flow rate. The GEM totalizes the rate information to account for fuel used. If you know how much fuel you started with and how much you have used you can figure fuel remaining by simple subtraction.

The pilot must supply an accurate starting fuel level for this subtraction to produce the correct fuel remaining result. Should the pilot overstate the fuel quantity on board, the GEM will dangerously overstate the fuel remaining and the endurance time as well. The pilot must be careful and diligent when setting the fuel on board.

Getting the correct fuel total on board is in many cases pretty easy. If you fill up prior to takeoff the number is obviously the total available on board. If you partially fill a known configuration (say tips empty) then the total is easy to calculate. If you partially fill fuel tanks or add an accurately know quantity to a poorly known original value - errors will abound. Unaccounted fuel loss from leakage, fuel vent overflow or theft will of course produce erroneous results. So be careful and the GEM will deliver safe, reliable, and convenient fuel information. But be sure to cross reference the information on the primary fuel quantity gauges. Never trust a single source of fuel information when you have two on board. Fuel exhaustion still ranks highly among accident causes. Don’t let your engine stop until you’re parked.