Probe Screen

The

Need for better Diagnostic Tools

The

Need for better Diagnostic Tools

Even the first GEM could detect an open probe and blank its indication. Over the years by helping owners and their mechanics trouble shoot instrument problems I developed a new understanding and sympathy for the challenge they faced.

Troubleshooting avionics is an expensive and time-consuming process. Often times the procedure requires access to the instrument connector for continuity measurements. This might take hours of instrument panel disassembly just to touch the connector. We needed something better, easier to use, less time consuming and therefore less expensive.

Why not have the instrument diagnose itself? Then you don’t have to disassemble the airplane or even touch the wiring. This is not as easy as it might seem. Adding resistance measurement hardware for each and every probe wire would more than double the complexity of the measurement system. I considered this carefully during the development of the GEM-610 second generation instrument. It would at least add a second PC board to the instrument and have even greater adverse impact on the GEMINI twin version. Even if we endured these problems to get the information we had no practical way to display it on an orange bar display.

So I abandoned it then, but revisited again this time. The new color display was certainly adept at displaying the information, eliminating that problem, but the resistance data was still hard to get.

So this time I was able to invent a new way of measuring resistance. The simple idea worked beautifully without adverse impact on the design. It was so simple in fact even I was skeptical at first.

Without this simple breakthrough we’d still be diagnosing things the hard way.

|

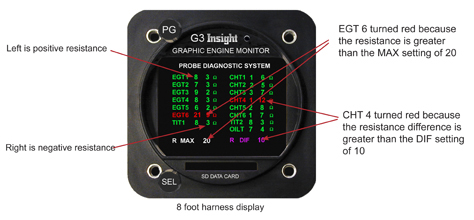

So what does the diagnostic system do?

The probe diagnosis page indications are in

green for normal readings and red for readings

that fail the criteria set at the bottom of the

screen.

Each temperature probe consists of two wires, a

positive lead and a negative lead. The two

numbers next to each identifier show the

resistance in Ohms of each lead.

For example, the line EGT1 8 3 means the

positive lead of the EGT1 probe has 8 Ohms

resistance, and the negative lead has 3 Ohms

resistance.

When the probe is new, it will have relatively

low resistance. As the probe ages, it’s resistance will slowly go up. Eventually, the probe will measure outside the pas/fail criteria you set at the bottom of the screen, and change from green to red, indicating that the probe should be replaced before it fails and leaves you with no temperature reading at all.

One other point to consider is that the longer

the wiring to the probes, the higher its

resistance.

Every foot of EGT wire adds 1.7 Ohms/ft for the

+ lead and 0.8 Ohms/ft for the - lead. Every

foot of CHT wire adds 0.8 Ohms/ft for the + lead

and 1.2 Ohms/ft for the - lead.

A 24 ft harness will fail the criteria that an 8

ft harness will pass with. That is why we allow

the user to modify the pass/fail criteria on the

bottom of the screen.

R MAX sets the maximum resistance (in Ohms) that

any single lead may have. If the R MAX is set to

20 Ohms a probe with either the positive or

negative leads measuring greater than 20 Ohms

will be annunciated in RED, otherwise its

displayed in GREEN. R DIF sets the maximum resistance (in Ohms) that the positive lead may differ from the negative lead. If R DIF is set to 10 Ohms, the positive and negative leads need to measure within 10 Ohms of each other to be annunciated in GREEN, otherwise its RED.

Proper setting on G1234 with 8, 10, 14 foot harness should be R MAX 20 R DIF 10 Proper setting on G1234 with 20, 24 foot harness should be R MAX 25 R DIF 15 Proper setting on G1234 with 30, 35 foot harness should be R MAX 30 R DIF 20 |